Our client, a major player in the production and supply of electricity in Newfoundland and Labrador (Canada), handles the generation and distribution of 80 % of the energy consumed in the province.

- Solutions

- Applications

- About

- News

- Careers

-

Our sites

-

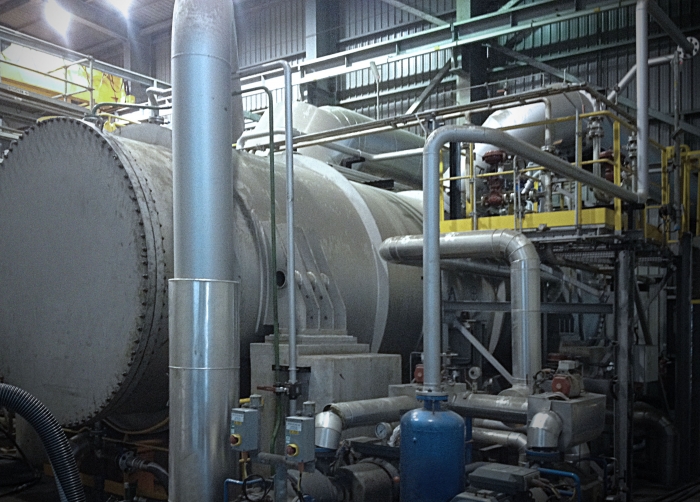

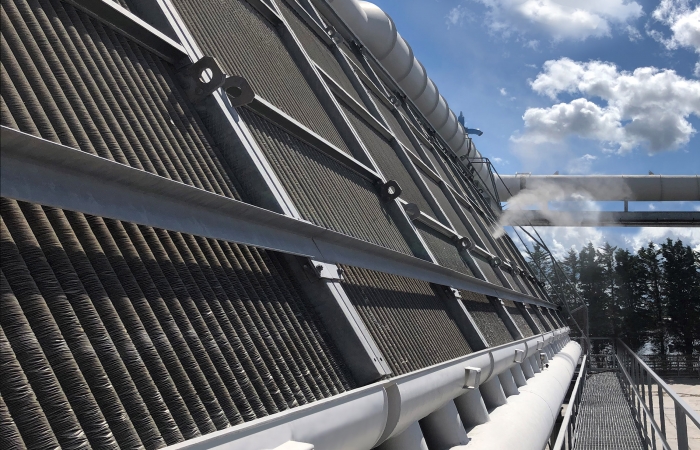

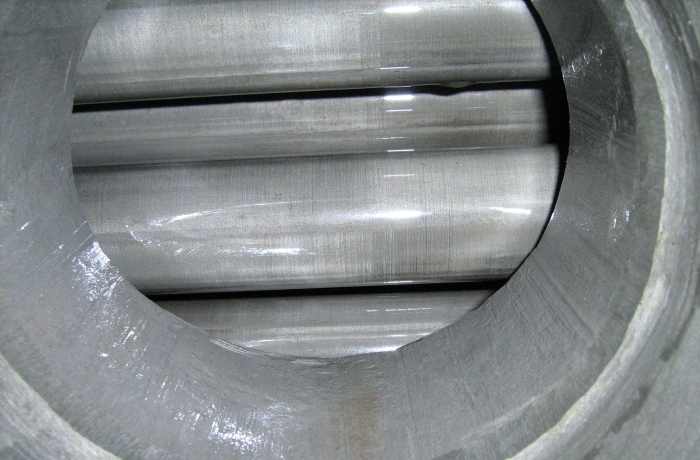

CTP equipment

Our rental and sale services for treatment units & equipment

-

CTP ambiente

A nossa filial em Portugal

-

CTP environment America

Our north american subsidiaries (USA & Canada)

-

- Contact

- FR

_Couleur CTP.jpg)

_couleur CTP.jpg)