- Solutions

- Applications

- About

- News

- Careers

-

Our sites

-

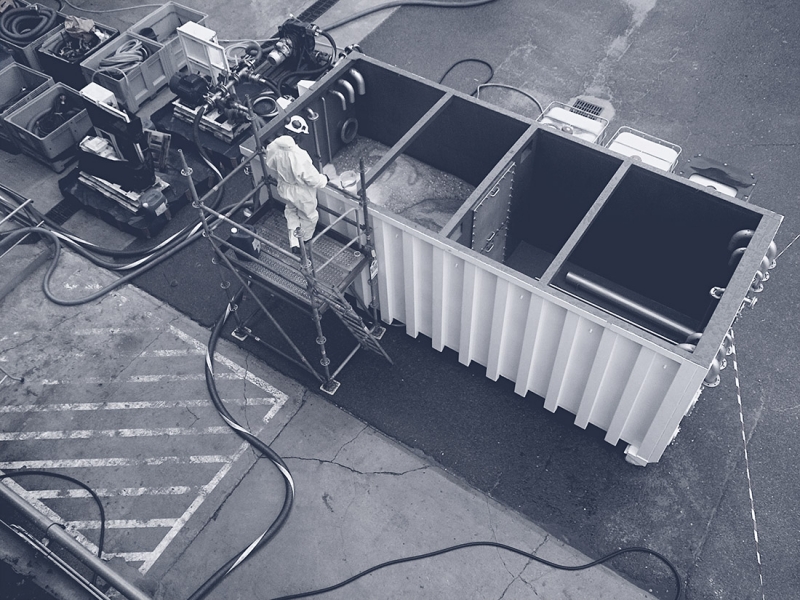

CTP equipment

Our rental and sale services for treatment units & equipment

-

CTP ambiente

A nossa filial em Portugal

-

CTP environment America

Our north american subsidiaries (USA & Canada)

-

- Contact

- FR