From pumping out material, to its disposal, CTP environnement offers a useful service, which saves time and money:

- Effectiveness: reducing both the equipment mobilisation and treatment time: up to 30 tons of dry matter per hour and 250 m3 (327 yd3 of liquid sludge treated per hour)

- Can be carried out keeping the storage facility online, minimising the impact on the rest of the site operation

- Allow the disposal costs to be segregated from the pumping/dewatering cost with an extremely competitive overall cost per ton of dry matter

The environmental benefits of our technology: low energy consumption (static dewatering) and potential recycling of dewatered sludge (compatible with landscape integration and/or phytostabilisation).

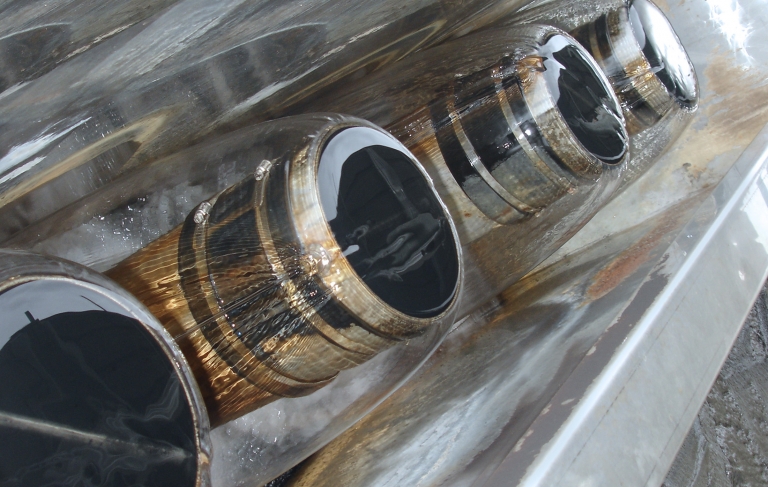

CTP equipment

CTP equipment

_couleur CTP.jpg)

Induxia 13b.jpg)