CTP environnement was approached for a pilot project financed by the French water agency, with delegated project management, to treat the lagoon located at the edge of the site, which collected mine water, rainwater, cooling circuit purges, tertiary effluents and laboratory effluents.

Discharge into the natural environment (rainfall episodes of up to 30,000 m3/d) was one of the outlets considered, taking into account the restrictive changes in the discharge order with :

- TSS & COD < 35 ppm

- Heavy metals (Fe, Cr, Ni, Cu, Zn): 1 to 10 ppb

(NB: exceeded by up to 1000 % to date)

Injection into the furnace cooling circuit was the second possible outlet for this water stored in the lagoon, but would require an improvement in water quality (equivalent criteria).

Pilot tests were to be carried out to assess the feasibility of a treatment system which would meet these objectives. The equipment had to allow metal insolubilisation, clarification, biological treatment and final filtration on several media and meshes to be tested.

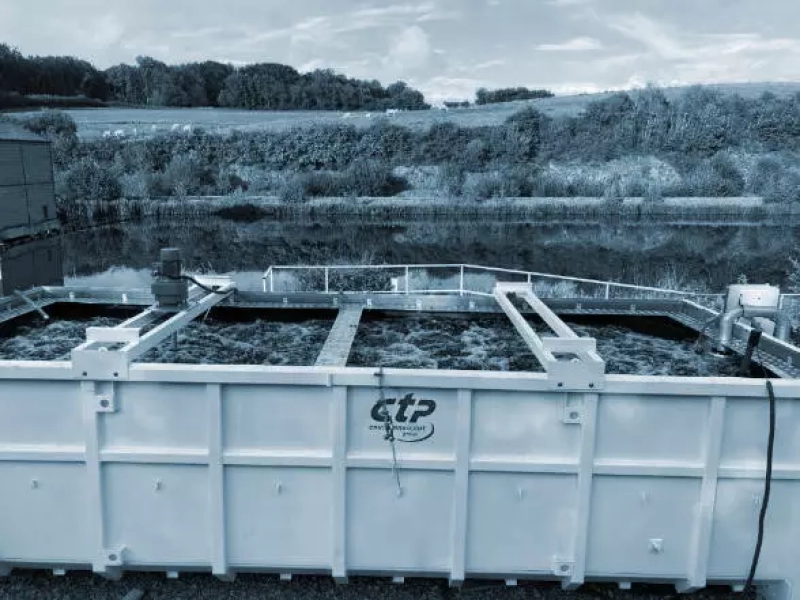

CTP environnement proposed the following solution:

- A stirred insolubilisation tank to which is added a mobile CLEARFLOW® unit: physico-chemical treatment allowing chemical conditioning of the effluent, separation by decantation and extraction of the sludge produced and installation of a mechanical filter.

- In a second phase, integration of the MBBR-type biological stage, after and then before the physico-chemical treatment.

The treatment unit ran continuously, operated by the customer with intuitive supervision allowing various settings and adjustments on site or remotely (remote management).

Various sensors, alarms and measuring instruments were installed in the process:

- Reliability and safety of the installation

- Control of the installation and data recording

- Process optimization

Several configurations were tested: without MBBR, MBBR before and after physico-chemical treatment, various filtering media, and cut-off points tested for finishing.

The analysis carried out daily showed:

- A significant reduction in heavy metal content using the physico-chemical process, as well as a reduction using finish filtration

- Final values around the limits of quantification

- Traces of hydrocarbons remained below the quantification limits

The pilot treatment trials met the initial requirements.

Investment decisions have been made.

CTP equipment

CTP ambiente

CTP environment America