A cogeneration power plant hired CTP environment Asia Pacific for its expertise in chemical cleaning

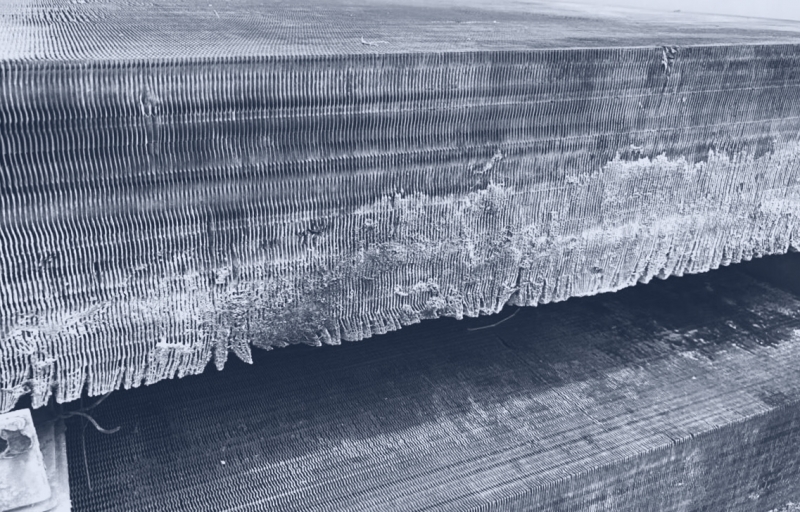

The air fin cooler bundles were initially completely covered by hard deposit due to previous cleaning with water jets. The water hardness used for these cleaning being very high, the minerals - mostly limestone - totally blocked the bundles after a few years. The customer could not remove it with any other process and was anticipating a complete replacement.

CTP Decamex® process was unknown in Thailand until early 2020.

After a first successful intervention, a test was carried out at the customer’s site replicating real conditions, to confirm the efficiency of the Decamex® process compared with another dry method (baking soda)

To compare like for like, the same parameters were applied:

- Quantity of chemicals

- Pressure

- Cleaning duration

- Distance between the nozzle and the bundles

The cleaning efficiency was compared using an airflow measurement, taken at multiple points below the bundles.

CTP Decamex® performance is self-explanatory with a significant air flow increase of +63 % against only +14 % with the baking soda method.

This airflow provides an improved heat transfer (impact on production) but also a regulation of the energy consumed by the fan motors (impact on energy savings/carbon balance).

The solid deposit was removed within less than 1 day and the customer retrieved a good cooling efficiency.

This result highlights the performance of CTP environment Decamex® process and the expertise of the CTP team. So far two AFC have been cleaned at this power plant. Including the success of this test, a total of five jobs have been carried out in Thailand from the beginning of 2020, including two other major Oil & Gas companies.

CTP equipment

CTP ambiente

CTP environment America