The aim is to restore the thermal capacities of heat exchangers, while maintaining the integrity of equipment.

Depending on the circumstances, this improved efficiency results in an increase in the flow of cooling water, a reduction in the circuit’s pressure loss, an improved process fluid temperature and, in all cases, a rapid return on investment.

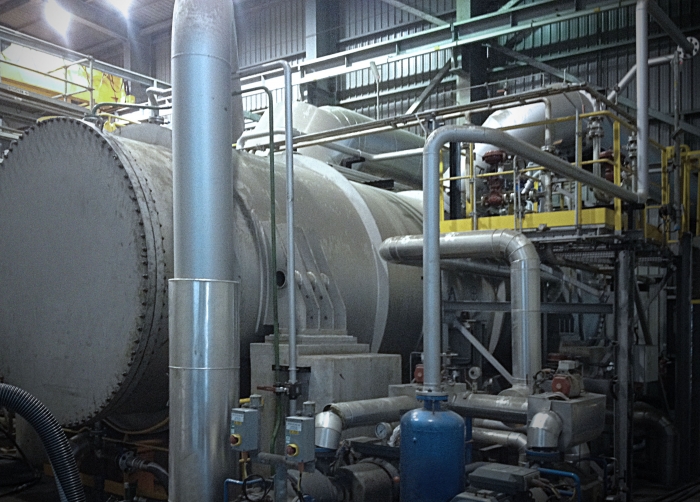

CTP equipment

CTP equipment